Fast - simple - reliable

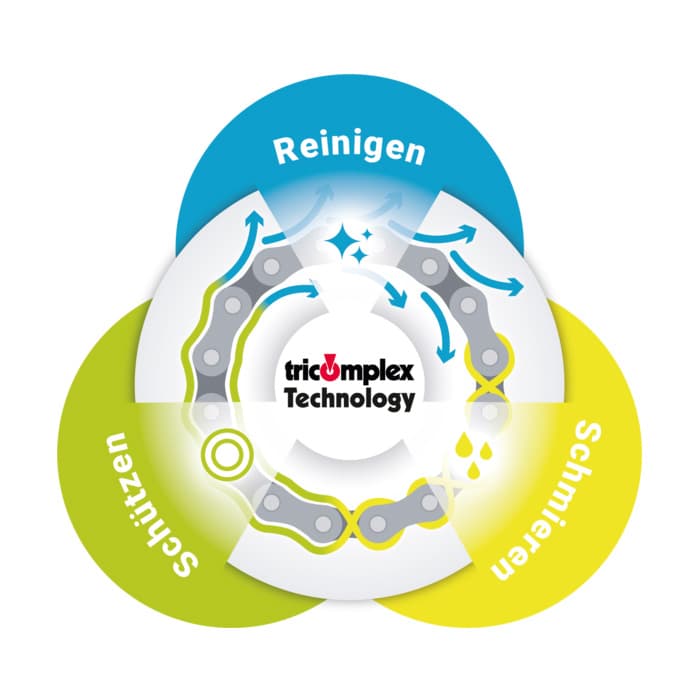

innotech tricomplex-Technology®

Three tasks combined into one

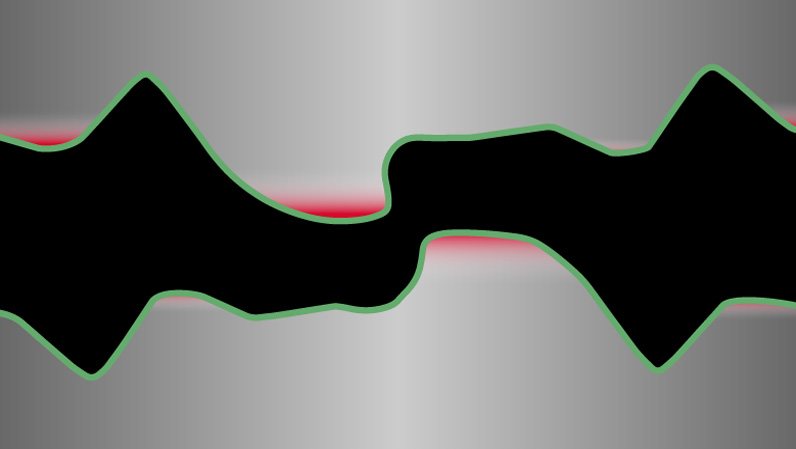

Specific active ingredients keep surfaces clean, properly lubricated and free from corrosion.

The innofluid® Additiv-Technik additive bonding to clean metal surfaces triggers a thermoplastic cold flow at defined pressure temperature pairings that results in metal smoothing and tempering.

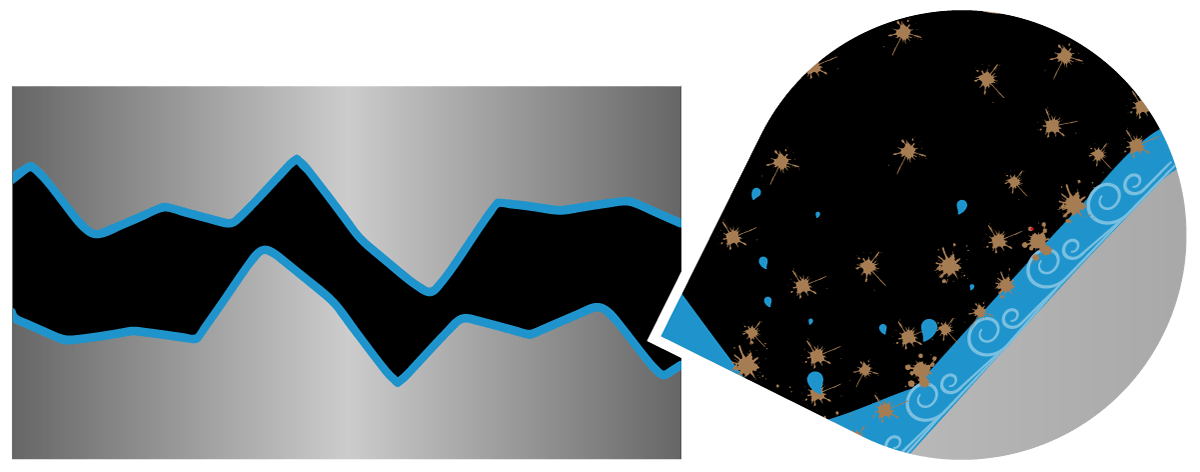

Cleaning

"Proper cleaning ensures appropriate lubrication." Employing task-specific hydrocarbon solvents makes sure surfaces are clean. Which is crucial when it comes to the effectiveness of innofluid® additives.

Lubrication

Using a synergetic mix of components for each task creates a bipolar surface effect that prevents dust adhesion. Means surfaces stay clean which extends the lubrication intervals.

Protection

Specific innofluid® additive compounds ensure that plant and machinery are protected form corrosion throughout the entire lubrication interval..

Your benefits

innotech´s tricomplex-Technology® meets the individual needs of each task. It forms the basis for clean, dry and appropriately lubed surfaces that lower friction and reduce overall wear and tear.

- Increased Durability

- Process Reliability

- Lower Energy Costs

What makes the difference?

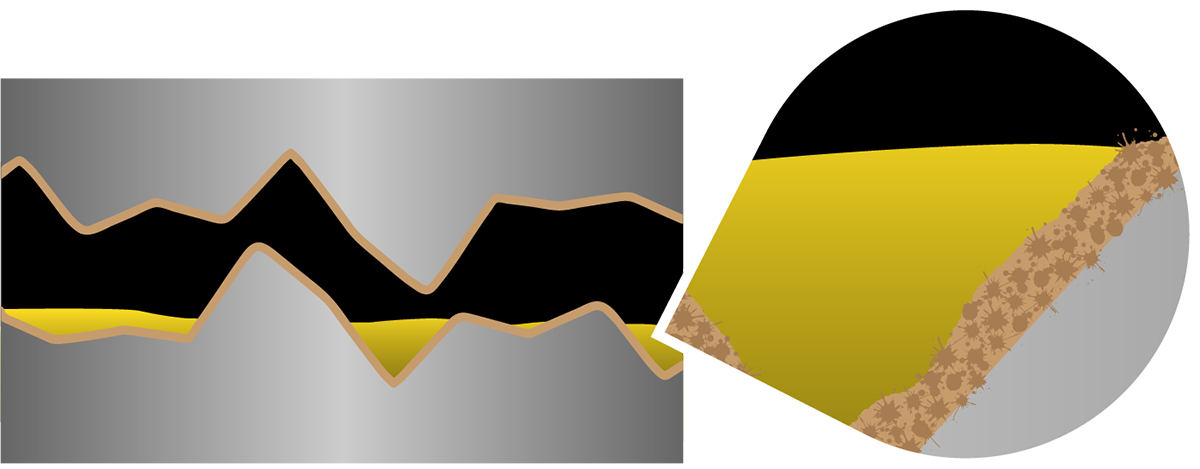

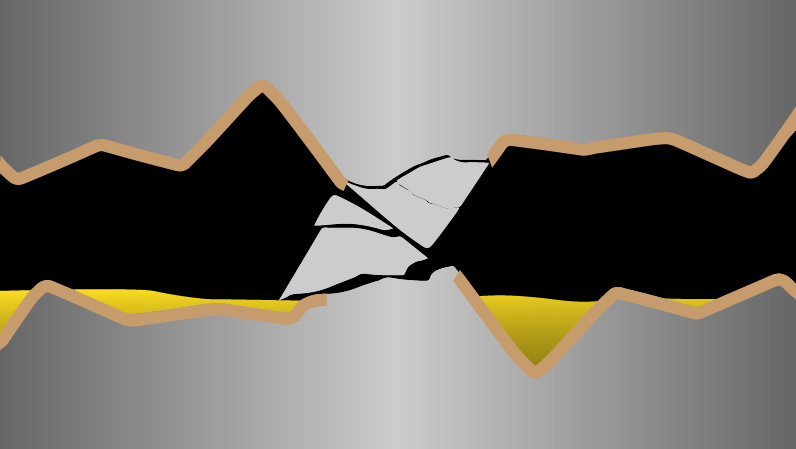

Conventional

1. No cleaning effect - No clean surfaces

Means lubricants don´t stick.

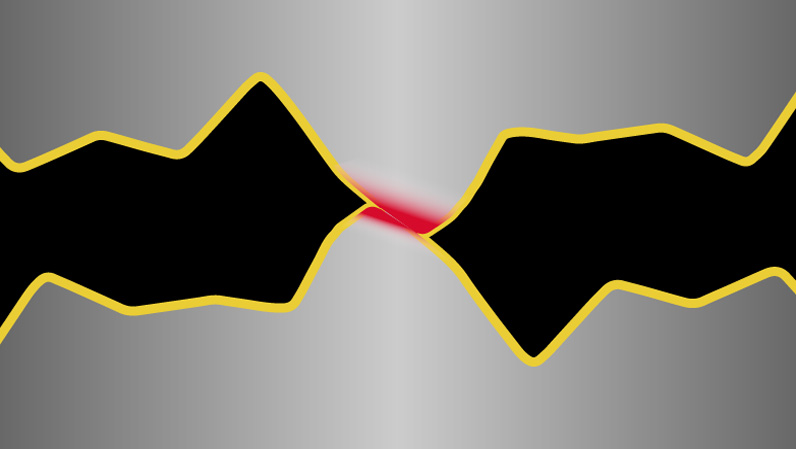

2. The peaks of the surface texture are not properly greased - more wear and tear

3. Grit accumulates in lubricant, increasing both friction and wear and tear.

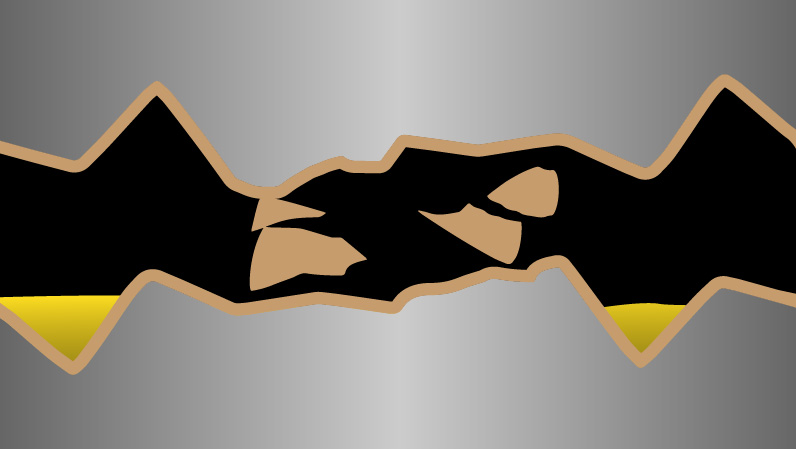

Tricomplex-Technology®

1. Clean surfaces make sure that lubricants stick

2. Pressure and temperature activate the innfluid additive, coating surfaces without any visible trace of wear and tear

3. Continual cleaning and lubrication hand in hand with surface smoothening and effective corrotion protection

Anwendungsbeispiel anhand einer Duplex-Antriebskette

Initial State of the Chain

One time use of Innotech 105 Synthetic Bearing Lubricant

After three Applications over the period of one work day

After Five applications over the period of two work days

Impacts of no-lube policy

These days, cutting back on lubricants (particularily, when it comes to chains) seems to be an easy way of reducing operational costs, as lubes are considered something that plant and machinery can "easily do without". However, proper lubrication not only prevents equipment damage and increases plant lifespan but helps save a tremendous amount of energy, as shown in the graph on the right. Moreover, the effect has been substantiated by a wide range of industry-leading companies.