The ideal chain lubricant

|

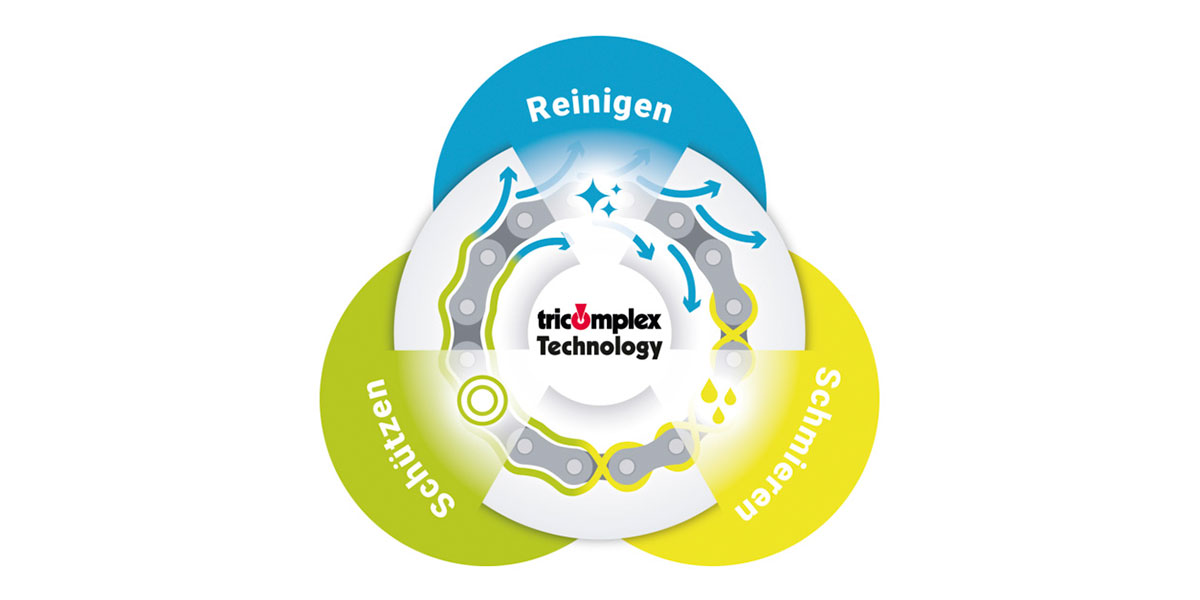

Reinigen |

Cleaning |

|

Schmieren |

Lubricating |

|

Schützen |

Protecting |

The task

One of the most important and demanding technical tasks is the optimal maintenance and care of drive, transport and load chains.

All good things come in threes

Firstly, the most important requirement here is that the chain is clean - this enables adhesion of the lubricant to the surface and achieves optimum coating of the chain.

Due to the problem of minimal spaces between the moving parts, a lubricant with extreme penetration is therefore required which covers all chain joints, inner bearings, drive bushings and spindles - in order to provide optimum lubrication and protection.

Thirdly, the different and sometimes difficult operating and ambient conditions require a lubricant that meets these high requirements.

The facts

Working influences and ambient conditions

The greatest risk to safe and effective chain lubrication is the often varying and difficult ambient influences. For example, external influences such as dirt and particulates cause dust particles to stick and become embedded. The resulting abrasive effect causes increased wear. A wet, damp and chemically aggressive environment also leads to corrosion in the inner bearings and drive bushings of the chain - which are thus exposed to increased friction. Resinification by mineral oil as well as coking and decomposition particles due to high temperatures have an extremely negative effect on lubrication. In addition, very high surface pressures accelerate wear enormously.

Initial lubrication and re-lubrication

Basically, a distinction is made between the initial lubrication (for new drive components) and re-lubrication. Re-lubrication must be compatible with the initial lubrication. No chemical reactions (e.g. resinification or acid formation) and no separating layer must form which would prevent penetration into the inner bearings of the chain during re-lubrication.

The criteria

What criteria are now decisive for optimum lubrication? To achieve optimum chain lubrication, the lubricant must be able to:

1. clean the chain of dirt, deposits and resinification as well as to loosen and flush particles from surfaces which are subject to friction;

2. penetrate into the narrowest spaces, such as chain inner bearings, chain drive bushings and spindles, in order to provide not only surface lubrication but also to achieve comprehensive lubrication of the chain;

3. build up good surface adhesion without itself sticking, so as not to bind dust or dirt;

4. build up a durable lubricating film and withstand high mechanical loads.

The solution

The unique chain lubrication and cleaning system in the high performance "innotech" product "SIS 105" synthetic inner bearing lubrication 105 (more here) penetrates to the critical points of the chain and provides cleaning and lubrication in a single operation!

The combination of various organic solvents based on hydrocarbons - in combination with lubricating substances - ensures that old deposits such as resin build-up are dissolved and flushed out. At the same time a non-greasy, wear-resistant lubricating film is built up uniformly across all the surfaces of the chain parts - especially in the inner bearings - as a result of the slow evaporation of the solvents.

The technological edge

Due to the innofluid® additive technology, thermoplastic flow deformation takes place on the contact surfaces under pressure and temperature conditions. With a minimum of wear the surface irregularities are turned into a new, evenly smoothed and hardened surface. At the same time additives protect against corrosion and are capable of displacing moisture.

The proof: comparative tests with other chain lubricants - on penetration capacity, lubricating properties and corrosion protection - demonstrate the unique advantages of this technology!

For more information about the innotech tricomplex-Technology® together with the innofluid® additive, please visit here.